Executive Director Mervi Ahola leads the Finnish Indoor Air Association, which has been actively sharing theme information in Finland for over 30 years. A good indoor climate is the sum of many factors, and new university research on the subject is constantly being conducted. The association is an important link to increase the dialogue between researchers in the construction industry and those who need information.

In the Nordic countries, the level of requirements of building regulations has traditionally been higher than in the rest of Europe. For example, in Finland, they also contain minimums for the ventilation air volume of buildings. It is indeed more difficult to verify the implementation of the practice.

The HVAC field is a combination of technology and closeness to people

Mervi Ahola of the Finnish indoor air association has practically been dealing with indoor air quality throughout her working career. We asked her to tell us who is responsible for good indoor air. At the beginning of the interview, it is interesting to hear what made her specifically choose the Master of Science in HVAC studies.

– In the beginning I was interested in the combination of technology and closeness to people. Indoor air is practically at its best when you don’t even notice it. In this case, the human influence and the acquired experience and knowledge bring a different dimension to the technology.

– When the topic is discussed, it is good to first verify what is meant by different terms. When talking about indoor air quality, it automatically includes possible pollutants. In addition to cleanliness, the indoor climate also includes thermal conditions. Correspondingly, the indoor environment also covers lighting and acoustics in addition to the above, Ahola elaborates.

At the same time, she emphasizes that ventilation plays a significant role in creating good indoor air, but the condition of the buildings’ structures and maintenance during their life cycle are just as important.

Who takes responsibility for indoor air?

In public discussion, indoor air quality is easily brought up in connection with problems such as mold-damaged buildings.

– This is an emotional topic and articles that gain visibility in the media/social media also affect public opinion. When it comes to best practices, it clearly divides people. Our goal in the association is to produce fact-based information to support solutions. Today, even right down to the consumer level.

Ahola reminds that the association operates impartially and has networked with many different organizations, the business world, and authorities. University research in the construction industry as well as practical property management professionals are represented on the board of the association.

– Yes, good indoor air is a matter for all parties during the property’s life cycle, but ultimately it is the property owner’s responsibility. After all, the responsibility starts with the customer, in other words, what kind of quality level is required. And from there it flows to the desks of the architect and the HVAC designer and on to the contractor. After construction, it is important that essential information about the property is transferred to maintenance, whose task is to ensure that the conditions remain good even during use. In the entire chain, communication between the parties is needed. If mistakes are made during the construction phase, or the right equipment is installed incorrectly, success cannot be achieved, Mervi Ahola sums up.

Ahola emphasizes the responsibility of the entire chain equally. Even the last in the chain, i.e. the user of the property bears his share of the responsibility.

– The lifestyles of the users and residents of the premises naturally affect the quality of the indoor air. In addition, neglecting maintenance measures and necessary maintenance can quickly ruin a well-planned and built entity.

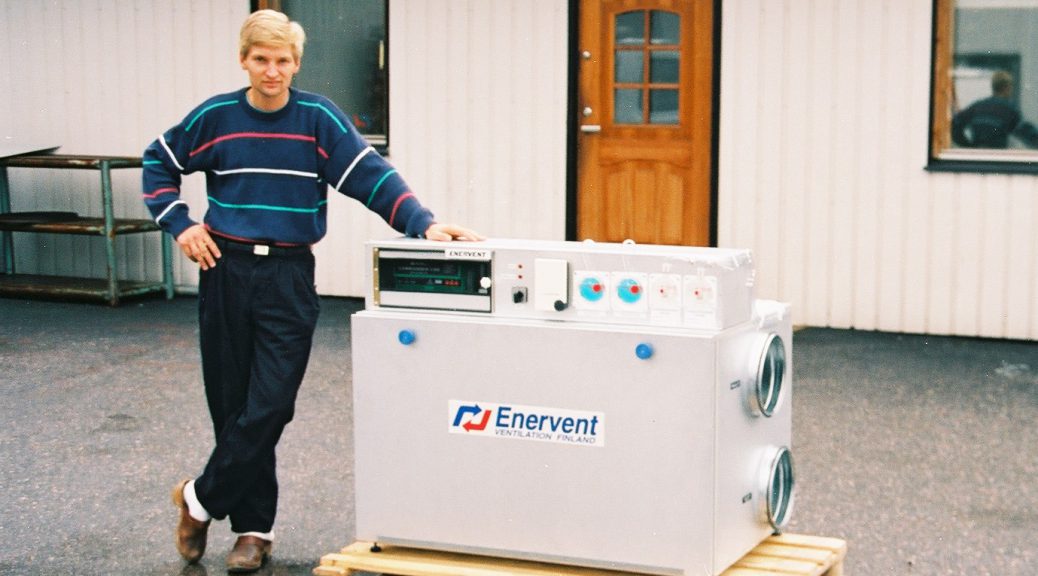

Finnish Society of Indoor Air Quality and Climate (FISIAQ) is a non-profit Society, that promotes the work for healthy and comfortable indoor air quality and climate. The Society provides information from research to practice and educates the users and the owners of buildings to maintain a good indoor climate. FISIAQ was founded in 1990 to organize the Indoor Air Conference 1993.