In February it was 35 years since Tom Palmgren started working at Enervent Zehnder. During this time, the development of ventilation units has progressed by leaps and bounds. But chance had its hand in the game when Tom ended up in the business.

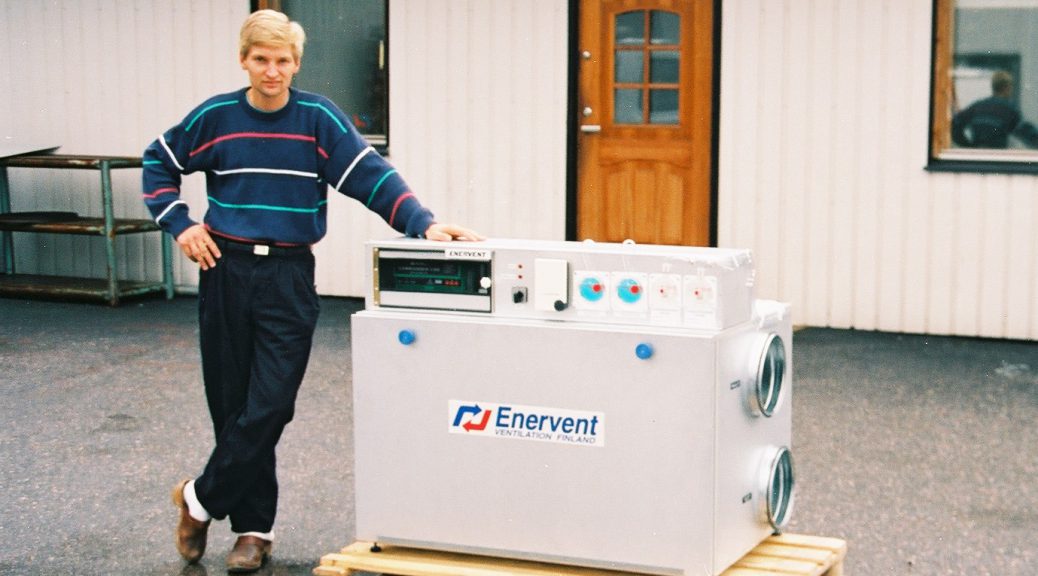

When an energy engineering student from Loviisa was thinking about the topic for his diploma thesis in the late 1980s, he took out the telephone directory for his county. Combinent was at the beginning of the alphabet and CEO Robert Hägg answered the call. The phone call was the start of a more than 30-year career in ventilation technology.

From a thesis to a working career

Just a few years before Tom called, Hägg, an entrepreneur in the metal industry, himself a technology-enthusiastic innovator, had manufactured the first ventilation units.

– At the first meeting, I immediately received a proposal for the topic for my final thesis. I studied HVAC engineering as a specialization option and at Combinent I focused on the rotary heat exchanger in my work. Tom says that his entire career began somewhat by chance with the study of heat recovery with rotary heat exchangers.

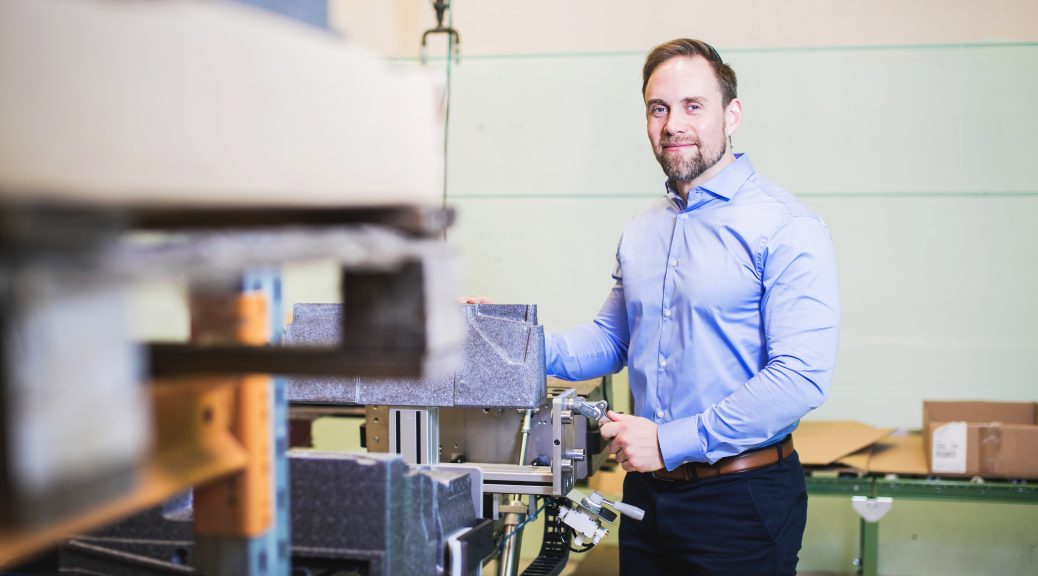

He has been in several different positions, the common thread in his career has always been development.

– In the beginning I was doing product design and electrical and automation design. I have also been involved in sales and made offers. Sometimes technical support has been needed in the customer interface. After all, accounting has never been assigned to Tom.

Growth and internationalization

In the early 2000s, Combinent’s name became Enervent. Tom moved to the position of technical director when Ensto, an international family company in the electrical industry, bought the ventilation manufacturer from Porvoo.

– The business had grown steadily, and production was separated from product development under Ensto. Then it also became my responsibility to monitor the regulation at both national and EU level. Related to that, my duties include quality issues and certifications as well as monitoring of standardization work, Tom lists the job description today.

Advances in technology

It is easy for Tom Palmgren to name the most important milestones from a technology perspective.

– The company’s success is based on the right choice of strategic technology, i.e., switching to the rotary heat exchanger. The next significant change was the development of digitalization, the change from AC fans to DC fans and the transition to heat pump technology. In this way, we made our units more energy efficient than before, which is an important competitive advantage even today.

During the last ten years, development has been rapid and customer oriented. Among other things, digital connections to various property management systems and development of mobile solutions have been an automatic continuum. In addition, the effect of the regulations will become increasingly important in product development.

What made you stay with the company for so long?

– Managers and owners have always had an encouraging attitude towards new development ideas and their testing. This has also been realized in recent years as part of the Zehnder Group. The most important thing, of course, is the good spirit in the working community that has been preserved despite growth and changes.